Among the many quality indicators of product packaging, pressure resistance is a fundamental and crucial factor determining whether it can safely reach the end consumer. Whether it's a plastic bag carrying goods or a medical infusion bag related to life and health, the static and dynamic pressures it endures during warehousing, stacking, and long-distance transportation directly test the physical limits of the packaging. Packaging bag pressure resistance testers are core testing equipment that quantifies this limit and verifies the reliability of packaging structures, building a solid line of defense for product safety for enterprises.

Packaging failures often stem from unforeseen pressures. Imagine a logistics warehouse with boxes stacked high, the bottom layers of packaging bags bearing hundreds of kilograms or even more. If the packaging material's pressure resistance is insufficient, or the heat seal is weak, it can lead to slow deformation or even sudden rupture, causing leakage, contamination, and economic losses. For infusion bags, this risk is even more severe; even minor damage can introduce microorganisms, leading to serious medical safety issues. Packaging bag pressure resistance testing can accurately simulate these scenarios, allowing for the early detection of weaknesses in packaging design, materials, or processes in the laboratory, thereby avoiding potential risks in real-world applications.

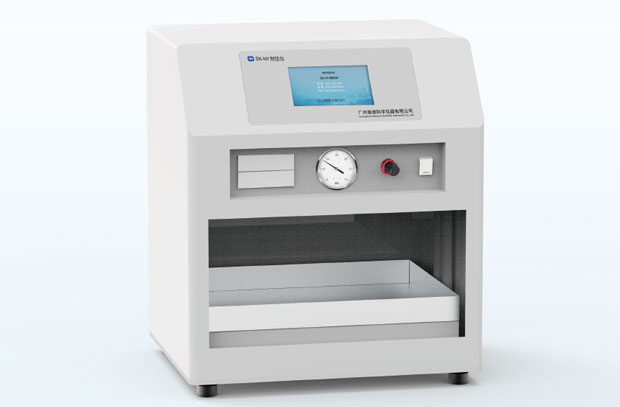

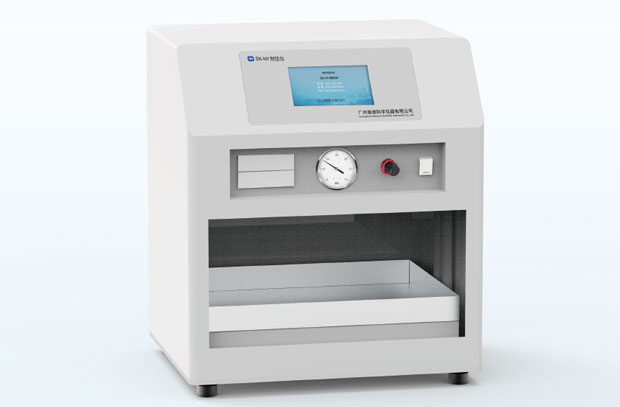

The working principle of the packaging compression strength tester is scientific and rigorous. The equipment applies uniform and controllable compressive force to the packaging sample through a precise pressure loading system. During this process, the instrument monitors and records the relationship between pressure values ??and packaging deformation in real time until the packaging ruptures or reaches the preset maximum pressure. The final maximum compression resistance data provides an objective and quantitative basis for evaluating packaging quality. This not only helps companies determine whether their current packaging meets distribution requirements but also guides them to optimize packaging solutions, such as adjusting material thickness, improving structural design, or scientifically specifying the number of stacking layers in warehousing, achieving cost control while ensuring safety.

As industries increasingly prioritize product quality and safety, relevant national standards and industry regulations are becoming more stringent. Many sectors have made the pressure resistance of packaging a mandatory testing item. Using standard plastic packaging pressure resistance testers for compliance testing has become standard practice in the supply chain management of leading manufacturers. It is not only a passport to meeting regulatory requirements and successfully entering the market, but also powerful proof that a company demonstrates its rigorous quality control system to customers and consumers, helping to build a reliable brand image.

From a macro-level business perspective, investing in professional packaging bag pressure testing capabilities is essentially an efficient risk management strategy. By conducting systematic stress testing at the production front end or incoming material stages, the risk of large-scale packaging failures can be minimized, avoiding potentially huge returns, compensation claims, and reputational damage. Simultaneously, the data assets accumulated through long-term testing constitute a valuable packaging database for the company, providing solid data support for new product development and continuous improvement.

In conclusion, the role of a packaging bag compression tester goes far beyond a simple "pass" inspection. It serves as a bridge connecting packaging design, manufacturing, and actual logistics applications, acting as a physical barrier to ensure product safety from the production line to the consumer. In an increasingly competitive market environment, incorporating packaging compression strength testing into core quality control processes is an inevitable choice for companies to demonstrate professionalism, fulfill product responsibility, and earn lasting trust.