Industry News

-

Electronic pendulum impact tester: A quality guardian protecting the impact resistance of packaging.Time:05.11.2025Impact resistance is a crucial indicator in the quality assessment system of packaging materials. It directly relates to a product's ability to effectively withstand external impacts and collisions during warehousing, transportation, and handling, thereby ensuring the safety and integrity of its contents. Among numerous testing methods, the electronic pendulum impact tester, with its scientific design, reliable data, and efficient testing process, has become an indispensable quality testing device in the packaging industry.

-

Time:04.11.2025In the packaging testing instrument industry, especially in the food, beverage, medical device, and cosmetic sectors, the long-term safety and stability of products are fundamental to a brand's survival. Simulating stringent sterilization and storage environments, and anticipating potential packaging risks, has become a crucial challenge for manufacturers. Against this backdrop, the high-temperature sterilization process and its core testing equipment— the high-temperature sterilizer —play an indispensable and critical role.

-

Time:03.11.2025In the highly competitive era of logistics and e-commerce, the strength of a single carton directly determines whether a product arrives intact in the customer's hands. Damaged packaging not only signifies financial loss but also deals a critical blow to brand reputation. So, how can we accurately predict the pressure limits a carton can withstand during stacking and transportation? The answer lies in a crucial quality control device – the Carton Compression Tester.

-

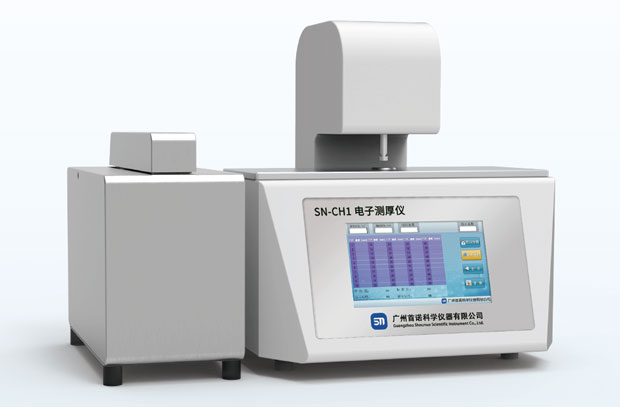

Time:29.10.2025In the soft packaging industry, material thickness is a key parameter affecting its physical properties, barrier properties, and service life. Whether for plastic films, sheets, paper, corrugated cardboard, textile materials, non-woven fabrics, or solid insulating materials, precise thickness measurement is directly related to product quality control and improvement. Therefore, the film thickness tester, as a high-precision inspection instrument, has become an indispensable quality control tool for many soft packaging manufacturers.

-

Time:23.10.2025Discover why professional labs choose Five-Point Heat Sealers like the SN-RF5. Learn how it maps the Heat Seal Window in one test, boosting R&D efficiency for packaging, food, & pharma. Get the expert guide.

-

Time:21.10.2025What is the role of a seal testing machine in packaging? Our in-depth analysis explores how seal testers (like Shounuo's SN-MF1/MF2) use the vacuum decay method to prevent leaks, ensure product safety in food & pharma, and protect brand reputation. Discover the critical technology behind packaging quality control.

-

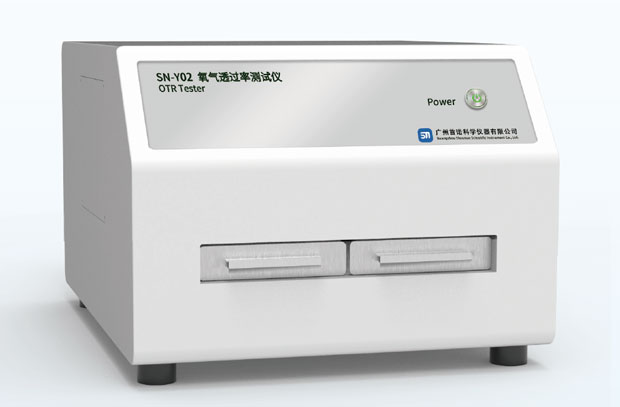

Time:20.10.2025In the packaging quality control of food, pharmaceuticals, cosmetics, and electronic products, the packaging material's oxygen barrier properties are a key factor in determining product shelf life and quality. Therefore, choosing an accurate and efficient otr tester (also often called an oxygen permeator or oxygen permeation meter ) is crucial. With numerous brands on the market, this article will review several representative brands in the industry (in no particular order) and introduce Guangzhou Solutia Scientific Instrument Co., Ltd., a domestically produced company whose technical principles are aligned with international standards.

-

Time:16.10.2025This article provides an in-depth analysis of the core working principles, mainstream testing methods (gravimetric method and infrared sensor method), key purchasing considerations, and multi-industry applications of the Water Vapor Transmission Rate (WVTR) Tester (also known as Moisture Permeability Tester). It offers a comprehensive WVTR testing solution to ensure the barrier properties and safety of product packaging.

-

Time:14.10.2025In the pharmaceutical industry, drug quality and safety are paramount. The performance of packaging materials (pharmaceutical packaging materials) that come into direct contact with drugs directly impacts their stability, effectiveness, and safety. Barrier properties are a key performance indicator for pharmaceutical packaging materials, determining their ability to effectively resist the intrusion of gases like water vapor and oxygen, while preventing the loss of active ingredients.

-

Time:29.09.2025In packaging for food, pharmaceuticals, electronics, and medical devices, the oxygen barrier performance of materials directly affects product shelf life, safety, and functionality. The Oxygen Permeability Tester (also known as OTR Tester) is a critical instrument for evaluating this performance, providing key data for material development, quality control, and packaging design.